GATRON RO PLANT

CLIENT

GATRON

PROJECT

RO PLANT INSTALLATION

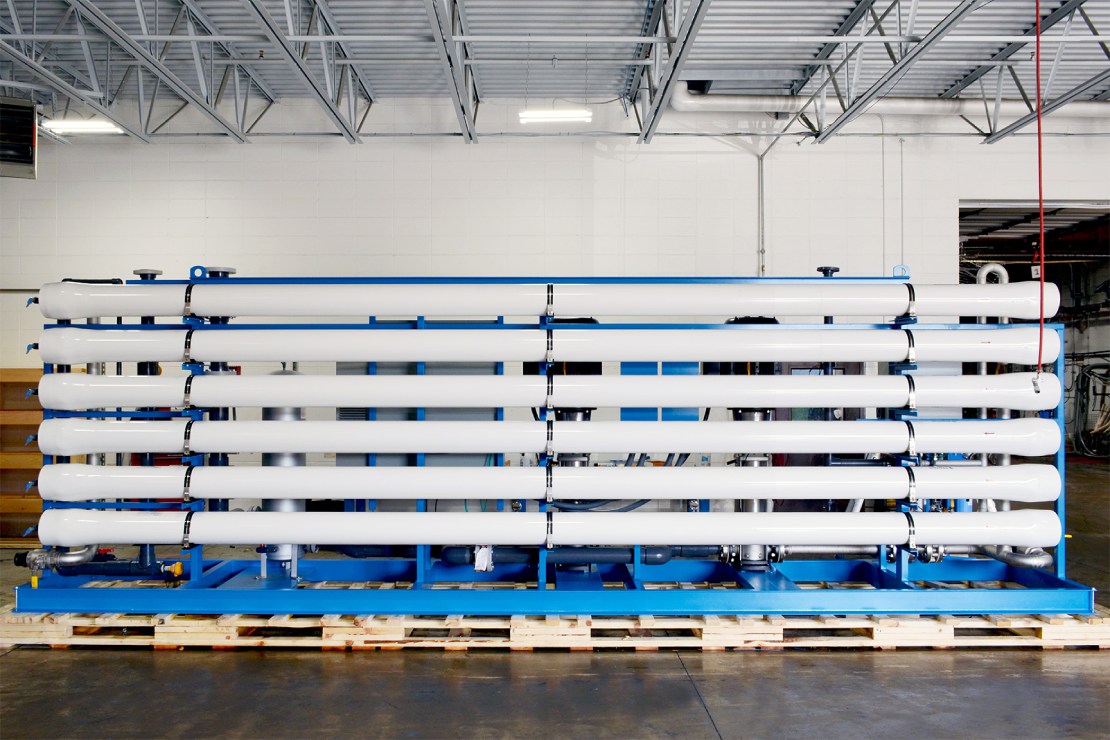

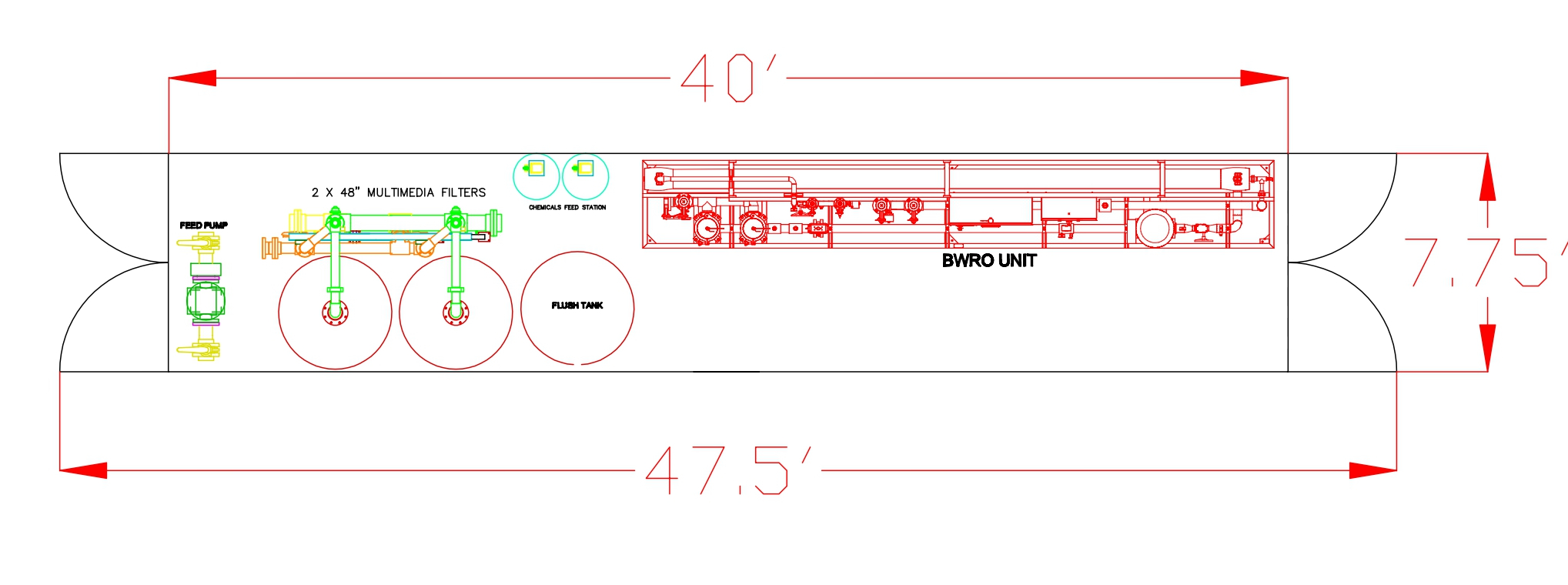

BRACKISH WATER REVERSE OSMOSIS PLANT INSTALLATION

Gatron Industries pvt (LTD) approached us with a project in which they wanted to install a Reverse Osmosis Plant in their factory to have a constant supply of drinkable water for its employees, and have fresh water available for its daily tasks in the plant. Their target was 110,000 IGPD capacity plant. Here is how we went about solving this problem for them.

OUR PROPOSED SOLUTION

PLANT DETAILS

RO FEED PUMP

Centrifugal Multistage Vertical S.S 316 Pump (Grundfos)

Pressure: 50 Psi

Motor: 10HP/7.5KW

Pressure: 50 Psi

Motor: 10HP/7.5KW

RO PRESSURE PUMP

Centrifugal multistage Vetical S.S 316 pump (Lowara)

Pressure: 50 PSI

Motor: 50 HP/37KW

Pressure: 50 PSI

Motor: 50 HP/37KW

MULTI MEDIA FILTER

2 x 48″ media filter

FRP material with gravel

Sand garnet & authracite

With complete piping

FRP material with gravel

Sand garnet & authracite

With complete piping

CARTRIDGE FILTERS

2 x 5 micron wound cartridge

2 x housing of PP/FRP

Rated for 150 psi

With isolation valves

2 x housing of PP/FRP

Rated for 150 psi

With isolation valves

CLEANING PUMP

Centrifugal Multistage Vertical S.S 316 pump (Lowara)

1 x TEFC motor, 5HP 380V

1 x TEFC motor, 5HP 380V

RO MEMBRANE

24 x GE thin film spiral-wound membrane 8″x40″

4 x FRP pressure vessels from BEL composite

4 x FRP pressure vessels from BEL composite

SYSTEM INSTRUMENT

1 x Schneider PLC & HMI RO control panel

Main Power 380V, 3 phase, 50 Hz

Central RO panel enclosure NEMA 12 rated

NEMA 4X rated electrical component and condute

Main Power 380V, 3 phase, 50 Hz

Central RO panel enclosure NEMA 12 rated

NEMA 4X rated electrical component and condute

CLEANING SYSTEM

Permeate flush

1 x 500 gallon polyurethane tank

1 x centrifugal pump 316 S.S

1x manual PVC butterfly valve

1 x PVC sch. 80 piping

1 x level switch

1 x pressure guage

4 x cleaning hose

1 x 500 gallon polyurethane tank

1 x centrifugal pump 316 S.S

1x manual PVC butterfly valve

1 x PVC sch. 80 piping

1 x level switch

1 x pressure guage

4 x cleaning hose

CHEMICAL FEED SYSTEM

Antifoulant & Caustic

2 x 50 gallon Polyethylene tank (22″ Dia)

2 x Walchem positive displacement pump

2 x Level switch

2 x Fitting and Tubing

2 x 50 gallon Polyethylene tank (22″ Dia)

2 x Walchem positive displacement pump

2 x Level switch

2 x Fitting and Tubing